Centre of Excellence

Our Core Belief

|

At Magnatech the Center of Excellence (CoE) is constituted by a team of experts that provides leadership, evangelization, best practices, research, support and/or training for a focus area. Though the main focus it to innovate and develop state-of-art products within the market segments targeted by Magnatech, it sometimes does develop products that use the components developed by Magnatech, based on customer needs. The CoE team is a group of people including technology experts, production specialists and industry experts. |

Magnatech believes in maximizing the utilization of the CoE model to not only improve production efficiency without compromising on quality but also reduce manufacturing costs which can effectively be passed on to customers. Some of the key areas of CoE participation are:

- Reduce production costs.

- Constantly improve operational efficiencies by measuring and reporting KPIs.

- Optimize the manufacturing environment with the best raw material at the lowest cost.

- Raise the standard of quality.

- Quantify and manage product/component quality and performance issues from a customer usage perspective.

- Share knowledge and best practices across departments and LOBs, raising the value of existing intellectual capital.

- Improve morale among shop floor teams by increasing their visibility within the organization and their effectiveness doing their jobs.

- Take lead role in developing new product idea into a prototype, test and make it production ready.

- Keep abreast of new technology that can be used in the production process.

Innovations

Despite enormous improvements in manufacturing technology, manufacturers of electronic components are constantly facing the challenge of producing products that are smaller, more powerful, safer, and faster but also value for money.

The Magnatech management actively supports all innovation ideas as a top priority. The end goal is simple, it should benefit the customer. Some of the features of innovation exercise are:

- Constant lookout for innovative technologies

- Identify and develop ideas that extend our value-added chain to customers.

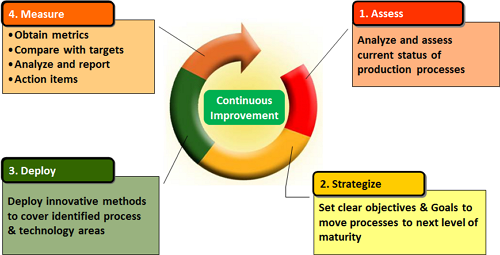

Continuous Improvement Process

Any process, even if it working perfectly now, has scope for improvement. The improvement may come in the form of production cycle time, optimal utilization of resources and reduction in wastages both in material as well as wait time and defect fixing time.

The improvement cycle goes through 4 definitive steps:

- Assess

- Strategise

- Deploy

- Measure

Each cycle comes up with incremental improvement ideas, however small they may be. These ideas are developed in order to integrate them with the manufacturing process. Before actual deployment, they are tested to ascertain feasibility and once satisfied it is introduced in production. The outputs are measured to ascertain the impact of the change in processes.